In today’s competitive marketplace, product development is not just about creating something new—it’s about creating something that works flawlessly, delivers value, and stands out from the competition. One of the most crucial steps in the product development process is prototyping, where ideas and concepts are translated into physical representations. Prototype molding services play a vital role in this stage, allowing businesses to refine their products before going into full-scale production. The rapid evolution of prototype molding technology has enabled companies to streamline their development process, reduce costs, and improve the quality of their final products. In this article, we will explore how expert prototype molding services are revolutionizing product development.

The Importance of Prototyping in Product Development

Prototyping is a fundamental aspect of product development because it allows designers and engineers to test, evaluate, and refine their concepts in a tangible form. Rather than relying on abstract ideas, companies can physically interact with prototypes, identify flaws, and make necessary adjustments before committing to full production. This process not only saves time but also mitigates risks by ensuring that products meet functional, aesthetic, and ergonomic standards.

By utilizing prototype molding services, businesses can produce high-fidelity prototypes that closely resemble the final product. These prototypes help stakeholders visualize the product in a way that sketches or 3D models cannot. Whether it’s evaluating the fit and feel of a consumer electronics product or ensuring the safety and performance of a medical device, prototypes provide critical insights that influence the final design and manufacturing process.

How Prototype Molding Services Enhance Product Design

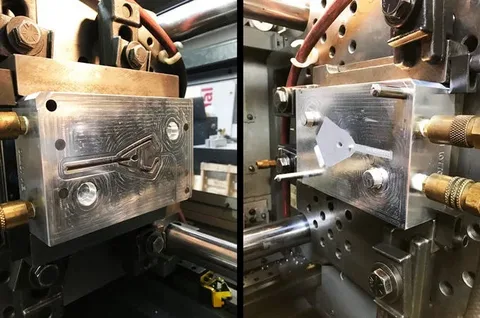

Prototype molding services are essential in turning early concepts into working models. Using advanced techniques such as injection molding, casting, and additive manufacturing, prototype molding services allow designers to quickly create multiple iterations of a product, testing different materials, shapes, and functionalities. This iterative process is vital for product designers as it enables them to refine designs based on real-world testing.

The benefits of prototype molding extend beyond just design validation. It also helps in optimizing product features, ensuring that every element of the product, from its materials to its shape and size, performs to the desired standards. With expert molding services, companies can develop prototypes that are not only visually accurate but also functional. This is particularly beneficial for industries where precision and performance are critical, such as automotive, medical, and consumer electronics.

Speed and Efficiency: The Role of Prototype Molding in Accelerating Development

Time is one of the most significant constraints in product development. The faster a company can bring a product to market, the better its chances of capitalizing on consumer demand. Expert prototype molding services have revolutionized the speed at which prototypes can be created, drastically reducing lead times in the design process. With the use of rapid prototyping technologies such as 3D printing and advanced injection molding, businesses can create high-quality prototypes in a matter of days, rather than weeks or months.

This speed and efficiency allow for more iterations, enabling designers to test multiple variations of a product without delays. Furthermore, rapid prototyping reduces the need for extensive tooling and expensive equipment, making it more cost-effective for small to medium-sized businesses to engage in product development. As a result, companies can meet tighter deadlines, reduce the time to market, and gain a competitive edge by introducing innovative products more quickly.

Cost-Effectiveness of Expert Prototype Molding Services

Prototype molding services can be seen as an investment that pays off in the long term. While creating prototypes may initially seem expensive, it is far more cost-effective than proceeding with mass production without adequate testing. Without prototypes, companies risk launching products that are flawed, which could lead to costly recalls, rework, or reputational damage. By using prototype molding, businesses can catch design flaws early, saving significant amounts of money that would otherwise be spent on fixing mistakes after production.

Furthermore, prototype molding services allow for the use of cost-effective materials and techniques that simulate the final product without the high costs associated with full-scale production. By utilizing 3D printing, for example, companies can create prototypes with complex geometries at a fraction of the cost of traditional manufacturing methods. These cost savings enable companies to allocate their budgets more effectively, investing in other critical aspects of product development, such as market research or marketing efforts.

The Future of Prototype Molding Services in Product Development

As technology continues to evolve, so too does the potential of prototype molding services. Emerging technologies, such as artificial intelligence (AI), machine learning, and advanced robotics, are poised to further revolutionize the prototyping process. These innovations promise even faster turnaround times, greater design precision, and more efficient production methods. In particular, AI can be used to optimize the design process, identifying potential issues and suggesting improvements based on data from previous prototypes.

In addition, advances in materials science are expanding the possibilities of prototype molding. New materials with enhanced properties, such as increased durability, flexibility, or heat resistance, are being developed to meet the ever-growing demands of various industries. As these new materials become more accessible, prototype molding services will continue to play an essential role in helping companies develop products that are not only innovative but also capable of meeting the stringent standards required in today’s marketplace.

Conclusion

The integration of expert prototype molding services into the product development process has been nothing short of transformative. By allowing companies to create high-quality, functional prototypes quickly and cost-effectively, these services have streamlined product development, reduced risks, and accelerated time-to-market. As technology continues to advance, the potential for prototype molding to further revolutionize product development is immense. By leveraging the power of prototype molding services, businesses can ensure that their products not only meet consumer expectations but also lead the charge in innovation within their respective industries.