In the world of medical device manufacturing. Precision is more than just a goal. It is an absolute necessity. The production of medical devices requires the highest standards of sterility, reliability, and quality. This is where cleanrooms for medical devices play a crucial role. The design of cleanrooms tailored specifically for the medical device industry ensures that these controlled environments meet the stringent standards required for high-quality production. This article explores the vital relationship between cleanrooms for medical devices and the role of cleanroom design in ensuring precision and compliance in the medical device manufacturing process.

Cleanrooms for Medical Devices: A Critical Necessity for Quality

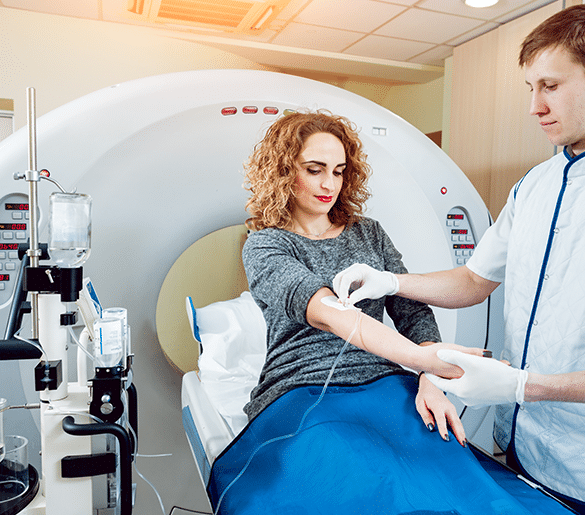

Manufacturing medical devices is a complex, highly regulated process. These devices directly impact patient health and safety. So maintaining a sterile environment is essential. Cleanrooms medical devices are designed to minimize the risk of contamination, ensuring that medical devices are produced in a controlled and sterile environment. These cleanrooms adhere to rigorous cleanliness standards, providing the ideal setting for the safe and compliant production of medical devices.

Cleanroom Design: The Backbone of Precision in Medical Device Manufacturing

Cleanroom design plays a fundamental role in creating the controlled environments necessary for medical device manufacturing. It blends both science and art, focusing on the careful construction of facilities that meet the exacting demands of the medical device industry. Effective cleanroom design ensures that manufacturers have the required infrastructure to minimize contamination and preserve the integrity of their products.

Precision in Every Aspect of Cleanroom Design

When designing cleanrooms for the medical device sector, every detail must be meticulously planned to meet the industry’s strict standards. Key elements of this process include:

- Customised Solutions: Cleanroom designers collaborate with medical device companies to fully understand their specific needs. Whether it’s for assembly, testing. Or packaging, each cleanroom is designed to meet the exact requirements of the medical device manufacturing process.

- Material Selection: The materials chosen for constructing the cleanroom must not only be durable but also non-reactive and easy to clean. Cleanroom designers ensure that the materials used support the cleanroom’s sterility standards, ensuring a hygienic environment.

- Contaminant Control: The control of contaminants, particulates, and microorganisms is vital in any cleanroom. Particularly those for medical device manufacturing. Cleanroom design engineers use advanced ventilation and filtration systems to maintain a pristine environment that meets stringent cleanliness standards.

Regulatory Compliance: Meeting Industry Standards

The medical device industry is governed by strict regulations. Such as those from the FDA and CE Marking (for the European market). Cleanroom design ensures that every cleanroom for medical devices complies with these regulations. Failure to meet these standards can result in product rejections, regulatory penalties, and legal consequences. Cleanroom design professionals are well-versed in these regulatory frameworks, ensuring that every aspect of the cleanroom meets or exceeds the necessary guidelines.

By focusing on regulatory compliance, cleanroom design helps manufacturers achieve high levels of safety and reliability in their medical devices, ensuring they pass the necessary approvals for market release.

Conclusion: A Symbiotic Partnership for Medical Device Manufacturing

The collaboration between cleanrooms for medical devices and cleanroom design is essential in meeting the exacting standards of the medical device industry. Cleanroom design ensures that medical device companies have access to controlled environments that comply with regulatory requirements and provide the precision needed for high-quality manufacturing.

As the medical device industry continues to innovate and evolve. The synergy between cleanroom design and cleanrooms for medical devices will become even more critical. Together, they support the production of medical devices that help improve patient health and safety worldwide. By focusing on precision, cleanliness, and regulatory compliance. Cleanroom design guarantees that medical devices are manufactured in environments that healthcare professionals and patients can trust.